Concrete waterproofing is essential for maintaining the structural integrity of buildings in Singapore, especially for HDB flats, condos, and landed houses. With the tropical climate’s frequent rainfall and humidity, water leaks and seepage can wreak havoc if not addressed promptly.

Let’s explore everything you need to know about concrete waterproofing, its importance, and the best solutions for preventing and addressing leaks in Singaporean homes.

What is Waterproofing in Concrete?

Concrete waterproofing refers to the application of specialized materials or techniques to prevent water and moisture from penetrating concrete structures. While concrete is naturally porous, making it vulnerable to water ingress, waterproofing ensures that these structures remain durable and impervious to water over time.

Waterproofing in concrete is a process that makes concrete structures impervious to water and moisture. It involves applying specialized materials or techniques to prevent water ingress, which can lead to issues like dampness, cracks, and structural damage.

Concrete, despite its strength, is inherently porous. Tiny capillaries within the concrete allow water to seep through, especially under pressure or prolonged exposure. This water ingress can lead to several problems:

Structural Damage:

Water intrusion weakens concrete by causing corrosion in embedded steel reinforcements, leading to cracks and compromised structural integrity.

Aesthetic Issues:

Stains, efflorescence, and peeling paint are common outcomes of untreated water ingress. These not only diminish the visual appeal but also signal deeper issues.

Health Concerns:

Persistent dampness promotes mold and mildew growth, which can adversely affect indoor air quality and health.

Costly Repairs:

Without waterproofing, small issues can escalate into major repairs, such as addressing spalling concrete or severe leaks.

Without effective waterproofing, these issues can escalate, leading to concrete slab dampness, peeling paint, and even mold growth.

What is the Best Way to Make Concrete Waterproof?

The best way to make concrete waterproof depends on the specific requirements of the structure, the level of exposure to water, and the type of environment the concrete will face. In Singapore, where heavy rainfall, high humidity, and frequent water-related challenges are common, ensuring proper waterproofing for concrete structures is crucial for long-term durability and safety.

However, the following methods are among the most effective in Singapore:

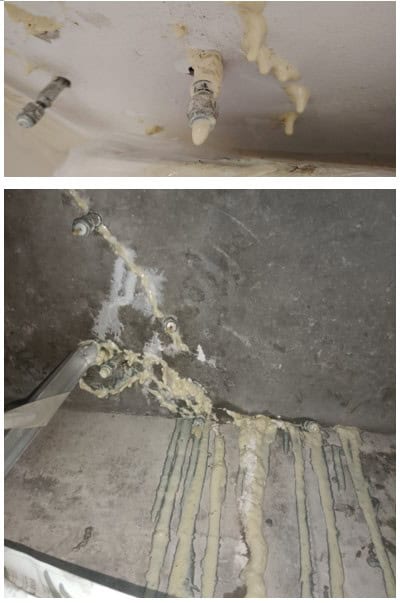

PU Injection Grouting

PU (polyurethane) injection grouting is highly effective for addressing active leaks in concrete. This technique involves injecting polyurethane (PU) resin into cracks or voids in concrete surfaces to seal cracks and voids, stopping water seepage instantly and preventing water penetration. This method is ideal for fixing ceiling water leaks, concrete slab leakage, and toilet water seepage without requiring extensive hacking.

Effective for Cracks and Voids

PU injection grouting works by filling even the smallest cracks and voids in concrete with a waterproof seal. Once injected, the polyurethane resin reacts with water and expands to form a flexible, impermeable seal. This ensures that all potential entry points for water are effectively blocked.

Quick and Non-invasive

Unlike traditional waterproofing methods, PU injection grouting is a relatively fast and non-invasive process. The injection can be done with minimal disruption to the property, making it ideal for both residential and commercial buildings. The procedure typically involves drilling small holes into the concrete, injecting the resin, and then sealing the holes—leaving little to no mess behind.

Durability and Flexibility

The polyurethane resin used in grouting is not only waterproof but also highly durable and flexible. This makes it resistant to shifting, cracking, or other damage that might occur due to changes in temperature or pressure. The flexibility of the material allows it to move with the concrete, providing long-term protection against water ingress.

Cost-effective

PU Injection Grouting is often more cost-effective than other waterproofing methods, such as installing waterproof membranes or carrying out extensive repairs. Since it targets only the problem areas, it saves on labor and materials, reducing overall repair costs. Moreover, it prevents the need for costly replacements of the concrete structure.

Minimal Disruption to the Structure

PU Injection Grouting doesn’t require extensive demolition or surface preparation. Since it’s a targeted repair solution, it minimizes the disruption to your property, allowing you to continue using the space while the waterproofing work is being done. It’s also suitable for retrofitting on existing buildings without requiring major renovations.

Long-lasting Solution

Once the polyurethane resin cures, it forms a strong, permanent bond with the concrete. This long-lasting effect ensures that the structure remains waterproof for many years without the need for frequent reapplications or maintenance.

Suitable for Various Applications

PU Injection Grouting is versatile and can be applied to a wide range of concrete structures, including walls, floors, basements, tunnels, swimming pools, and foundations. Whether it’s a residential, commercial, or industrial application, this technique can be customized to address the specific waterproofing needs of the structure.

Environmental Benefits

Polyurethane is an eco-friendly material that is non-toxic and safe to use in residential and commercial settings. The minimal waste produced during the injection process also makes it a more sustainable choice compared to other, more invasive waterproofing methods.

PU Injection Grouting stands out as one of the most efficient and reliable methods for waterproofing concrete. Its ability to quickly address cracks and voids, along with its durability and cost-effectiveness, make it an ideal solution for homeowners and businesses looking to protect their concrete structures from water damage. By opting for PU Injection Grouting, you can ensure a waterproof, long-lasting, and hassle-free solution that keeps your property safe from the damaging effects of water ingress.

Waterproofing Membranes

Waterproofing membranes, such as liquid-applied membranes, create a seamless barrier that prevents water from penetrating concrete surfaces. These are commonly used in roof waterproofing and balcony repairs.

Whether you’re dealing with basements, foundations, terraces, or walls, waterproofing membranes offer reliable and long-lasting protection.

Here’s why waterproofing membranes are considered one of the best options for concrete waterproofing:

Complete Protection Against Water Ingress

Waterproofing membranes create a continuous, seamless barrier over the concrete surface, preventing any form of water infiltration. Whether the water is from external sources (like rain or groundwater) or internal sources (such as plumbing leaks or moisture in the air), the membrane ensures the concrete remains dry and unaffected.

Versatility for Various Applications

Waterproofing membranes are versatile and can be used in various concrete applications, including foundations, basements, balconies, terraces, swimming pools, and roofs. They are suitable for both new construction and retrofitting on existing buildings. Membranes can be applied to vertical and horizontal surfaces, providing flexibility in a wide range of waterproofing projects.

Durability and Longevity

Waterproofing membranes are designed to withstand harsh weather conditions, extreme temperatures, and UV exposure, making them a durable and long-lasting solution for concrete structures. Many membrane types come with warranties of 10 years or more, providing peace of mind for property owners. Their resistance to cracking, peeling, and degradation ensures that the concrete remains protected for decades.

Easy Installation

Waterproofing membranes are generally easy to install, especially when compared to other waterproofing methods. They can be applied using different techniques, including rolling, spraying, or even torching, depending on the membrane type. For liquid-applied membranes, the application is as simple as spreading the coating evenly over the concrete surface. The ease of installation reduces the labor cost and overall time needed for the project.

Seamless Coverage

Unlike other waterproofing methods, such as sheet membranes or coatings, waterproofing membranes create a seamless barrier across the entire surface of the concrete. This eliminates the risk of water ingress through joints, seams, or weak spots, ensuring complete protection against leaks.

Flexibility and Crack Bridging

Concrete structures often expand and contract due to temperature changes and settlement. Waterproofing membranes, especially the flexible types (like EPDM and PVC), can accommodate these movements without cracking or losing their waterproofing capabilities. Some membranes even have the ability to bridge small cracks, maintaining the integrity of the waterproofing layer.

Low Maintenance Requirements

Once installed, waterproofing membranes require minimal maintenance. Regular inspections and cleaning are typically all that’s needed to keep the membrane performing at its best. This makes it a low-maintenance solution for property owners.

Resistance to Chemicals and Abrasion

Waterproofing membranes, particularly those made from materials like PVC and TPO, are resistant to a variety of chemicals, oils, and solvents. This makes them an ideal choice for environments where the concrete might be exposed to harsh substances, such as industrial facilities or areas near roadways with salt exposure. Additionally, these membranes are abrasion-resistant, ensuring they maintain their effectiveness even in high-traffic areas.

Cost-Effective Solution

While the upfront cost of installing waterproofing membranes can vary depending on the material and the complexity of the project, they are generally considered a cost-effective solution when compared to alternatives like traditional waterproofing systems or extensive structural repairs. Their long lifespan and minimal maintenance requirements make them a worthwhile investment.

Waterproofing membranes are a choice for concrete waterproofing due to their versatility, ease of installation, long-lasting durability, and ability to provide seamless protection. Whether you’re protecting a foundation, roof, basement, or balcony, waterproofing membranes offer a reliable and effective solution to keep your concrete structure dry, safe, and protected from water damage for years to come. Their ability to adapt to various concrete applications and environmental conditions makes them a top choice for property owners seeking peace of mind against water ingress.

Cementitious Waterproofing

Cementitious waterproofing is one of the most widely used and highly effective methods for making concrete waterproof, particularly for areas that are subject to water exposure like basements, foundations, and underground structures. This method involves using a special waterproofing mixture made of cement-based compounds that, when applied to concrete surfaces, create a durable, watertight layer.

Here’s why cementitious waterproofing is considered one of the solutions for concrete waterproofing:

Ease of Application

Cementitious waterproofing is known for being relatively straightforward to apply. The materials used in the mixture are typically in powder form, which, when combined with water, creates a slurry or paste that can be applied directly to the concrete surface using a brush, roller, or trowel. Unlike some other waterproofing methods that may require specialized equipment or expertise, cementitious waterproofing is easy for professionals to apply with minimal hassle.

Cost-Effective Solution

Cementitious waterproofing is often considered a budget-friendly option for waterproofing concrete structures. The ingredients used in the cementitious mix, such as cement, sand, and additives, are relatively inexpensive, making this method a cost-effective choice for both residential and commercial properties. Additionally, the long-term durability of cementitious waterproofing reduces the need for frequent repairs, further lowering costs over time.

Durability and Longevity

Once applied, cementitious waterproofing forms a durable, hard-wearing layer that is resistant to water penetration. It is highly effective in preventing water from seeping through the concrete, which helps protect the structural integrity of buildings. Cementitious coatings are designed to withstand various weather conditions, including rain and humidity, and they provide long-lasting protection against water damage. Depending on the product and the application, cementitious waterproofing can last for many years before requiring maintenance.

Ideal for Concrete Surfaces

Cementitious waterproofing is specifically designed to bond effectively with concrete surfaces, making it an ideal solution for concrete foundations, walls, floors, and other concrete structures. The application process involves filling the pores in the concrete, which creates a smooth, dense, and impermeable surface that prevents water from seeping through. Because concrete is a porous material, cementitious waterproofing helps block these entry points, ensuring complete protection against moisture.

Flexibility and Crack Bridging

One of the key benefits of cementitious waterproofing is its ability to bridge minor cracks and imperfections in the concrete. While the coating itself is rigid, many modern cementitious waterproofing products are designed to have some flexibility, allowing them to accommodate small movements in the concrete without cracking. This makes it an excellent option for areas that are prone to slight settling or minor shifts, such as foundations or floors.

High Resistance to Hydrostatic Pressure

Cementitious waterproofing is particularly effective in areas exposed to hydrostatic pressure, which occurs when water builds up and exerts force on the structure. This is common in underground structures, basements, and foundations that are in contact with groundwater. Cementitious coatings can withstand the pressure exerted by water, preventing water from entering the structure even when external conditions are challenging.

Breathability

Unlike some other waterproofing methods, cementitious waterproofing allows the concrete to “breathe,” meaning it permits the evaporation of moisture from within the concrete. This is particularly important for preventing the build-up of trapped moisture, which can lead to mold and mildew growth. The breathability of cementitious coatings helps regulate humidity levels within the concrete structure while still keeping external water from infiltrating.

Chemical Resistance

In addition to being water-resistant, cementitious waterproofing coatings offer a degree of resistance to various chemicals and contaminants, making them suitable for use in industrial environments or areas exposed to aggressive substances. This resistance helps protect the concrete from deterioration due to chemical reactions and ensures the waterproofing remains intact even in challenging environments.

Environmentally Friendly

Cementitious waterproofing is often considered an eco-friendly option, as the materials used in the mixture are typically non-toxic and environmentally safe. Unlike some chemical-based waterproofing treatments, cementitious products do not release harmful fumes or pollutants during application. Additionally, many cementitious waterproofing solutions are made with sustainable materials, which contribute to a lower environmental impact.

Prevents Mold and Mildew Growth

Because cementitious waterproofing blocks the passage of water while allowing moisture to evaporate, it significantly reduces the risk of mold and mildew growth. Keeping moisture from penetrating the concrete prevents the conditions necessary for mold to thrive, creating a healthier and safer indoor environment.

Low Maintenance

Once applied, cementitious waterproofing requires little maintenance. Regular inspections and cleaning are usually sufficient to ensure the surface remains intact. As the coating does not degrade easily, property owners can enjoy lasting protection with minimal effort.

Cementitious waterproofing is one of the methods for making concrete waterproof due to its simplicity, cost-effectiveness, durability, and ability to withstand water pressure and harsh environmental conditions. Whether for new construction or renovation projects, cementitious waterproofing offers reliable and long-lasting protection for concrete structures, making it a go-to solution for many property owners. Its versatility, ease of application, and ability to prevent water damage and moisture-related issues make it an ideal choice for safeguarding the integrity of concrete surfaces.

For homeowners seeking minimal disruption, non-hacking waterproofing methods like PU injection grouting and surface waterproofing coatings are excellent solutions.

Concrete waterproofing is not just about preventing leaks; it’s about enhancing the overall quality, durability, and safety of structures.

In Singapore, where weather conditions and water-related challenges are prevalent, waterproofing is a vital investment for homeowners and property managers alike. By safeguarding concrete against water ingress, you can enjoy long-lasting benefits, from cost savings to improved indoor comfort, while ensuring your building remains structurally sound for years to come.

For professional waterproofing services, consult a BCA-certified contractor today and enjoy a leak-free home!

Look no further than SWC Construction. Our team of experts is dedicated to providing hassle-free, efficient solutions tailored to your specific needs. Whether it’s concrete slab leaks or other waterproofing issues, we use the latest techniques and high-quality materials to ensure long-lasting protection and effective results. We manage each project with professionalism, making the process smooth and stress-free, so you can enjoy peace of mind knowing your property is in good hands.

Trust SWC Construction for seamless, worry-free waterproofing repairs – contact us today!